Difference between revisions of "Silversmithing (sage ability)"

Tao alexis (talk | contribs) |

Tao alexis (talk | contribs) |

||

| Line 1: | Line 1: | ||

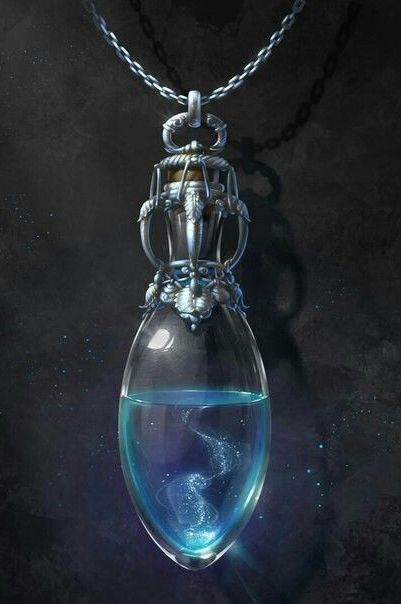

[[File:Silversmithing (sage ability).jpg|right|490px|thumb]] | [[File:Silversmithing (sage ability).jpg|right|490px|thumb]] | ||

| − | '''Silversmithing''' is an [[Knowledge Points|amateur]]-status [[Sage Ability|sage ability]] that enables the character to make jewelry and ordinary household objects of all kinds from lesser metals, including silver, pewter, brass, bronze, tin, copper and iron. The ability gives knowledge of the peculiarities of these metals and their use in making objects, such as how they ought to be handled or shaped. The character is able to judge the metal itself for its properties, but cannot make the metal; that is a different [[Puddling (sage ability)|sage ability]]. | + | '''Silversmithing''' is an [[Knowledge Points|amateur]]-status [[Sage Ability|sage ability]] in the [[Sage Study|study]] of [[Delicate Metalwork (sage study)|Delicate Metalwork]], that enables the character to make jewelry and ordinary household objects of all kinds from lesser metals, including silver, pewter, brass, bronze, tin, copper and iron. The ability gives knowledge of the peculiarities of these metals and their use in making objects, such as how they ought to be handled or shaped. The character is able to judge the metal itself for its properties, but cannot make the metal; that is a different [[Puddling (sage ability)|sage ability]]. The ability grants no special knowledge in the [[Selling Wholesale (sage ability)|sale]] or [[Bartering (sage ability)|bartering]] of any objects that are made. |

__TOC__ | __TOC__ | ||

| − | The | + | The work of a silversmith is distinct from that of a blacksmith in that it requires precision, delicacy and a controlled approach to working metal. While blacksmiths forge with brute force and extreme heat, the silversmith must carefully shape, join and refine metal using finer tools and lower temperatures. The trade relies on steady hands and an intimate understanding of how different metals behave when heated, hammered and joined. |

| + | |||

| + | The process of silversmithing involves cutting and shaping raw metal, joining components through soldering or mechanical connections, and refining the surface through polishing, etching or engraving. Items created can range from simple household goods such as cups, candlesticks and cutlery to ornate jewelry, decorative inlays or finely wrought religious artifacts. | ||

| + | |||

| + | The metals used vary in workability and value. Silver, being soft and highly malleable, is the easiest to shape but requires reinforcement through folding or backing to maintain durability. Pewter, a low-melting alloy of tin, is used for casting plates and vessels, though it lacks the lustre of silver. Brass and bronze provide durability and a golden sheen but require more effort to shape. Copper, while easily worked, is often used for decorative elements due to its tendency to tarnish. Iron, though not a precious metal, can be worked into fine chains or embellishments when combined with softer metals. | ||

== Tools == | == Tools == | ||

| − | The character requires | + | The character requires tools, including a small hammer and 3 lb. anvil, a hammer for dooming, a few fine pliers, blow-pipes, burnishers, scrapers, a die and punch, a pair of fine dividers and a delicate set of scales and weights. These comprise the chief appliances for a travelling jeweller. A square, strong table, some 5 ft. by 3, is necessary, as are the metals in the form of bars and plates. The character is fully able to flatten, fold, meld, solder or melt these metals for pouring, to produce the object desired. |

| + | |||

| + | More refined tools, such as gravers, chisels and chasing hammers, allow for decorative work, such as engraving or embossing. The use of polishing agents, from pumice to rottenstone, enhances the final finish of a piece. A steady heat source, whether from a brazier or a small forge, is necessary for softening metal or fusing components through soldering. | ||

== Time == | == Time == | ||

| − | With ordinary items, | + | With ordinary items, such as a cup or vessel, the amount of time required to create the object is a half-hour per ounce, plus one hour for any day the work must take place, to heat the fire and thence proceed. Thus, a tin cup weighing 8 ounces would require 4 hours to work the metal, plus one hour for the day or a total of five hours. |

| + | |||

| + | Detailed work, such as the making of jewelry or precise metals, requires a half-hour per ounce to ready the metal, which transforms the metal into parts small enough that they can be worked without the need of a fire. This secondary work requires four hours per ounce. This includes the time needed to burnish and smooth the piece, to whiten or clean it, and any other minor work needed. The result is an object of ordinary value, or market value that's unadjusted by the quality of work being done. This relates to an object's comparative [[Workmanship of Objects|workmanship]]. | ||

| − | + | The refinement process, particularly for silver, often involves repeated cycles of hammering, annealing and polishing to ensure that the final piece is strong, smooth and visually appealing. A skilled silversmith can take a simple ingot and, through patient work, transform it into an intricate piece that may be valued far beyond the raw material alone. | |

Revision as of 14:53, 7 March 2025

Silversmithing is an amateur-status sage ability in the study of Delicate Metalwork, that enables the character to make jewelry and ordinary household objects of all kinds from lesser metals, including silver, pewter, brass, bronze, tin, copper and iron. The ability gives knowledge of the peculiarities of these metals and their use in making objects, such as how they ought to be handled or shaped. The character is able to judge the metal itself for its properties, but cannot make the metal; that is a different sage ability. The ability grants no special knowledge in the sale or bartering of any objects that are made.

The work of a silversmith is distinct from that of a blacksmith in that it requires precision, delicacy and a controlled approach to working metal. While blacksmiths forge with brute force and extreme heat, the silversmith must carefully shape, join and refine metal using finer tools and lower temperatures. The trade relies on steady hands and an intimate understanding of how different metals behave when heated, hammered and joined.

The process of silversmithing involves cutting and shaping raw metal, joining components through soldering or mechanical connections, and refining the surface through polishing, etching or engraving. Items created can range from simple household goods such as cups, candlesticks and cutlery to ornate jewelry, decorative inlays or finely wrought religious artifacts.

The metals used vary in workability and value. Silver, being soft and highly malleable, is the easiest to shape but requires reinforcement through folding or backing to maintain durability. Pewter, a low-melting alloy of tin, is used for casting plates and vessels, though it lacks the lustre of silver. Brass and bronze provide durability and a golden sheen but require more effort to shape. Copper, while easily worked, is often used for decorative elements due to its tendency to tarnish. Iron, though not a precious metal, can be worked into fine chains or embellishments when combined with softer metals.

Tools

The character requires tools, including a small hammer and 3 lb. anvil, a hammer for dooming, a few fine pliers, blow-pipes, burnishers, scrapers, a die and punch, a pair of fine dividers and a delicate set of scales and weights. These comprise the chief appliances for a travelling jeweller. A square, strong table, some 5 ft. by 3, is necessary, as are the metals in the form of bars and plates. The character is fully able to flatten, fold, meld, solder or melt these metals for pouring, to produce the object desired.

More refined tools, such as gravers, chisels and chasing hammers, allow for decorative work, such as engraving or embossing. The use of polishing agents, from pumice to rottenstone, enhances the final finish of a piece. A steady heat source, whether from a brazier or a small forge, is necessary for softening metal or fusing components through soldering.

Time

With ordinary items, such as a cup or vessel, the amount of time required to create the object is a half-hour per ounce, plus one hour for any day the work must take place, to heat the fire and thence proceed. Thus, a tin cup weighing 8 ounces would require 4 hours to work the metal, plus one hour for the day or a total of five hours.

Detailed work, such as the making of jewelry or precise metals, requires a half-hour per ounce to ready the metal, which transforms the metal into parts small enough that they can be worked without the need of a fire. This secondary work requires four hours per ounce. This includes the time needed to burnish and smooth the piece, to whiten or clean it, and any other minor work needed. The result is an object of ordinary value, or market value that's unadjusted by the quality of work being done. This relates to an object's comparative workmanship.

The refinement process, particularly for silver, often involves repeated cycles of hammering, annealing and polishing to ensure that the final piece is strong, smooth and visually appealing. A skilled silversmith can take a simple ingot and, through patient work, transform it into an intricate piece that may be valued far beyond the raw material alone.

See also,

Bard Sage Abilities

Delicate Metalwork (sage study)